Oxygen generators are essential devices for both medical and industrial use. Whether you’re using a home oxygen generator for respiratory therapy or an industrial oxygen generator for aquaculture or welding, proper maintenance is critical for safety, performance, and longevity. This guide will walk you through the key steps, schedules, and tips to ensure your oxygen generator stays in top shape for years to come.

✅ Why Maintenance Matters

Without regular upkeep, oxygen generators can suffer from reduced efficiency, contamination risks, and even breakdowns that can jeopardize operations or patient safety. Proper maintenance:

-

Prolongs the equipment’s lifespan

-

Maintains oxygen purity and flow rates

-

Reduces energy consumption

-

Prevents unexpected downtime

🛠️ Basic Oxygen Generator Maintenance Tasks

Here are the most important tasks every operator or user should follow:

1. Clean or Replace Filters Regularly

Air filters trap dust, dirt, and bacteria before it reaches sensitive parts of the system. Depending on your model and environment, clean the intake filters every month and replace them every 3–6 months.

2. Inspect the Compressor

The compressor is the heart of your PSA oxygen generator. If it fails, the whole unit fails. Inspect for strange noises, excessive heat, or oil leaks every 6 months.

3. Check Oxygen Purity Levels

Regularly test the output oxygen concentration using a built-in or external sensor. If levels fall below 90–95%, it may indicate contamination or malfunction.

4. Clean External Components

Wipe down the unit, especially vents and display panels. Dust buildup can hinder airflow and heat dissipation.

5. Sensor and Valve Calibration

Sensors should be calibrated annually to ensure correct readings. Similarly, solenoid valves need to be checked and tested to prevent leaks.

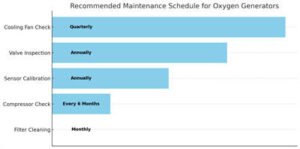

📅 Maintenance Schedule at a Glance

Here is a visual summary of the recommended schedule:

| Task | Frequency |

|---|---|

| Filter Cleaning | Monthly |

| Compressor Check | Every 6 Months |

| Sensor Calibration | Annually |

| Valve Inspection | Annually |

| Cooling Fan Check | Quarterly |

🔧 Troubleshooting Common Maintenance Issues

-

Low oxygen purity – Check the sieve beds and filters. Replace if needed.

-

Loud noise or vibration – Inspect the compressor and fan.

-

Overheating – Ensure fans are working and vents are clear.

-

No oxygen flow – Check tubing and valves for clogs or leaks.

🧰 Recommended Tools and Supplies

To maintain your oxygen generator, you may need:

-

HEPA or intake filters

-

Oxygen purity analyzer

-

Screwdriver and wrench sets

-

Cleaning cloth and alcohol wipes

-

Replacement sieve beds (if applicable)

📈 Bonus Tips for Longevity

-

Place the machine in a dust-free, well-ventilated space

-

Avoid overuse beyond rated capacity

-

Train staff on proper startup and shutdown procedures

-

Record all maintenance in a logbook

PubMed Study on Oxygen Concentrators

Conclusion

Maintaining your oxygen generator is not optional—it’s necessary for optimal performance and long-term reliability. With a simple maintenance routine, you can extend the lifespan of your equipment, improve safety, and ensure a stable oxygen supply at all times.

If you’re looking for a reliable oxygen generator manufacturer or need expert guidance on your system’s upkeep, feel free to contact us.